Quicker installation and easier operation

1. FAULT INDICATION BY A LEVER POSITION

At first sight you can distinguish if a

DPN has been switched-off by the user or

by a short-circuit or overload

top top

|

If a DPN is switched-off by the user, the lever

moves from the most upper position (3 = ON) to the extreme lower

position (2=OFF). A follow-up switch is led directly from the OFF

position to the ON position.

WARNING:

The DPN is able

to indicate a fault within a circuit, which has been caused by

short-circuit or overload. In that case, the lever falls down only into

the central position. When moving the lever upwards, it does not put any

resistance, so it seems to have a defect mechanism.

NEVERTHELESS, IT IS NO DPN – FAULT!

The task of such condition is to draw the user’s attention to the

fact that the DPN protective system had to reply on any outside matter

(short-circuit, overload). In that case, it is necessary to trace the

cause.

You can renew the DPN activity in the following way:

- at first, the control lever has to be moved from the central

position into the lower position (position 2 in the picture). When

moving, you must overcome a little resistance put by the internal

mechanism. It comes to the rearrangement (clicking) of the mechanism.

In this lower position, the mechanism is ready for the follow-up

switching.

- then, the lever is moved from the lower position into the upper

position (position 3 in the picture). During that motion, you can

recognize an usual resistance known by a normal switch-on of a device.

.

|

2. Locking Bar

A conductor will never be connected

incorrectly.

|

Terminal with locking bar:

|

|

Position A

– fully opened terminal

Position B

- the conductor begins to be tightened into the terminal

Position C

– partially tightened terminal, when the space underneath the terminal is

gradually closed by the locking bar

|

The design has been based on the fact, that every terminal has a so-called

“flat locking bar” in its movable bottom part. This locking bar is ejecting into

the space underneath the terminal, while the screw is being tightened. This

process avoids the conductor to be put-in under the terminal’s stirrup (as

happens by other DPNs) whereby it would not be possible to tightened the

conductor into the terminal.

A unique solution avoids the difficulties with connecting the conductors onto

a DPN. This principle excludes the possibility to place the conductor under the

terminal by mistake. In that case, the terminal would be tightened but,

unfortunately, without a conductor. If that mistake is not discovered during

installation by other DPNs, latent claim defects occur frequently. Such defects

occurred mostly at the end user (a conductor could be in contact with the

terminal but under a higher loading of the circuit, it burned-out and the

circuit was interrupted). The switchboard manufacturers had to bear additional

expenses for very „simple“ removal of such defects.

The above solution does not only avoid claims but it makes the installation

faster and contributes to the reliability.

top

top

3. Two-Line User's Inscription

Even if the

cover plate of a switchboard has been removed, you can still see which circuit

is protected by the DPN.

Each pole is equipped with an aesthetic transparent swing cover placed above the

switching-off lever. Under that cover, there is a paper two-line inscription

label put into slots. It is also possible to write on the plastic surface. The

cover has an arrestment in the upper open position.

4. Convenient Short Dimensions

There is more space for connecting

the conductors on the switchboard.

The

extraordinary small dimensions (especially the height is only 81 mm) rank the

DPN BONEGA® P-E-P to the smallest ones worldwide within the category of the

breaking capacity up to 6 kA.

The

extraordinary small dimensions (especially the height is only 81 mm) rank the

DPN BONEGA® P-E-P to the smallest ones worldwide within the category of the

breaking capacity up to 6 kA.

- the total depth from the pawl incl. the lever in OFF position is 73,23 mm

- the total depth from the DIN strip incl. the lever in OFF position is

67,23 mm

- the total depth from the DIN strip up to the surface is 61,6 mm

- the total height of the body is 81 mm + projecting pawl in operational

position: 5,2 mm

- control part’s height is 45 mm

- module width 17,6 mm

- user’s inscription (A): width 15,4 mm x height 6,2 mm + thickness 0,3 mm

In the switchboard (in the covered part), remains more space for leading and

connecting of conductors. This property can be appreciated especially when using

those DPN in small plastic household switchboards.

top

top

5. Casing Resistance to Gaping Upon Terminal Installation

There is no gaping of the DPN

casing or cross threading of

the terminal in the casing.

|

It is a relatively usual problem on other DPN´s – upon

an excessive screwing-up of the terminal, the casing opens or the

terminal crosses in the casing. On some DPN´s, even the joints and thus

the circuit are broken. |

It is avoided on the DPN´s BONEGA® P-E-P by means of:

- plastic guides for the movable parts of the terminal, which has been

chosen properly

- press-pieces in the casing body

- places for rivets, chosen properly

- plastic pins (the casing has no butt joins)

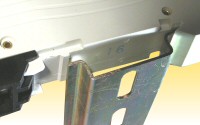

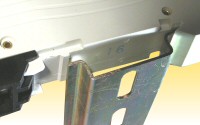

6. Attach the DPN onto a Flat Surface without DIN Strip

No problem in assembling to an old

breaker box.

|

|

|

|

Play animation

|

|

You will appreciate that advantage – a possible attachment of our

DPN

directly onto the flat surface without using the DIN strip - especially when

repairing old switchboards. This possibility do not require any modification of

the DPN.

How to do it:

- Screw a flat-headed screw into the flat area at the required position.

Leave that screw at a distance of approx. 5 mm from the surface (not

fully screwed).

- Onto the prepared screw put the DPN which has a corresponding cut in

its upper part.

- Draw out the arresting pawl to its final „open“ position in the bottom

part and then fasten the DPN by another screw to the flat surface through a

hole in this pawl.

The connection created in such a way is unusually strong.

|

top

top

7. Increased Vertical Stability on the DIN Strip

When tightening the

terminals,

the DPN on a DIN strip will be straight.

|

This news on the DPN BONEGA® P-E-P is a very essential

improvement of vertical stability, while the conductors are connected to the

device. When drawing up the terminals, the DPNs tend to incline and it is

necessary to “pre-stress” them manually.

The high stability has been reached by a plastic stop on the DPN bottom.

After attachment of the DPN onto a DIN strip, this stop functions as the

“contra-pressure” (with the torsional stress of the DPN´s body). In contrast

to the competitors, the movable pawl has only the holding function.

The other hand does not have to engage itself with “pre-stressing” of the

DPN and can be concentrated only to hold the conductor to be connected.

This measure accelerates the installation and makes is easier

|

top

top

8. CONNECTION OF INPUT OR OUTPUT FROM BOTH SIDES

A possibility to connect the input as

needed.

Input or output can be connected both onto the upper and lower terminals

without impairing the function of the DPN in any way.

Through this advantage, the mounting is easier and the distribution arrangements

at the switchboards can be variable.

You will appreciate it especially in the switchboards with a multi-row

arrangement – you can connect the input between two rows (saving of conductors

and time)

9. Large Terminals

Even a big cross-section of the

conductor

will not surprise you.

|

Within the entire range of nominal currents´ values (up to

32 A), it is possible to use a conductor with a cross-section up to 16 mm2

for a full conductor and 11 mm2 for a stranded conductor.

The emergency solution by some additional terminals, when the contact

resistances can occur, does not take place.

top top

|

10.

Strong Design of Terminals

Impossible to strip the threads even

with excessive stress.

The movable terminal has been made of one piece. In contrast to other DPN´s, the

joint has been solved by means of an overlapping and not by a so-called “puzzle

joint”. Through this overlapping, there goes a screw. It has a double thread

length available, which restricts the breaks – “stripping” the thread

essentially. The possibility to break it when being mounted is fully

excluded even if the torsional stress allowed by the standard is exceeded. (more

than 2 N.m)

The clip terminals themselves have in their bottom part also the cross

grooves which avoid the conductor to be taken out from the terminal (after

being drawn up, the conductor sinks into the grooves). Simultaneously, the

contact resistances are limited. (because of the enlargement of the

transmission area the burning of the conductors is not possible).

The junction of a conductor and a DPN is very rigid and reliable.

11. Locking Protection

The BONEGA® P-E-P DPN´s cannot be locked

from the outside.

This property protects the electro installation companies

against claims, which are caused by the end user, who can be proved wrong with

difficulties.

As the most products, also the DPN´s BONEGA® P-E-P has an

indication of the contact conditions. That indicates a real contact condition

and not only a position of the switch-on lever. In case of “sintered” contacts

and switched-off lever, the user is clearly informed about flowing current. As

the only ones, our DPN´s have that indication covered with a transparent

plastic sight-glass with a lens (magnifying) effect.

Reasons:

-

Because the indication is closely connected with a movable

contact, it happens on other DPN´s that the movable contact is locked

through the indication by means of a toothpick or a matchstick; thus the

complete thermal and short-circuit protection of a DPN is out of function.

It is not possible to do that on the DPN BONEGA® P-E-P, just because of that

transparent sight-glass

-

Dust protection

The DPN is equipped with a colored indication of contact

condition, which is independent on the lever position, and it depends just on

the real contact condition. In addition, this indication is protected against

dust penetration into the DPN by a transparent plastic cover with magnifying

effect.

top

top

12. EASY LINK-UP OF THE ACCESSORIES ONTO A DPN

An easy and fast connection of the

accessories.

The plentiful accessories can be linked-up on the left side of the DPN. The

interconnection of the accessories with the DPN is done, as follows:

- 1. Remove the grey self-adhesive plate, which covers the interconnecting

hole on the DPN´s left side (with nail or screwdriver) in accordance with the

type of the accessories.

- 2. Set up the DPN into the OFF position

- 3. With an easy “snapping” into place without any tools, connect the

accessories to the DPN.

The DPNs can be connected with plentiful accessories (low-voltage release,

voltage release, auxiliary contacts etc.). All those elements extend the

application of the DPNs by overvoltage or undervoltage protection, control,

regulation, remote control, remote indication of switch-on and switch-off

positions of a DPN, programming and measurement. Those combinations enable the

DPNs to be applied for the control of complicated automation processes.

These elements can be mutually interconnected (e.g. DPN + undervoltage

release + auxiliary indicating contact etc.), thus they can form different

combinations

top

top

13. ARBITRARY INSTALLATION POSITION

The operational position without

influence

on the safe function.

The construction and seating of an ejecting coil for short-circuit release

affect the DPN function in various positions almost solely. In principle the

question is if the weight of the coil core helps or limits the kinetics of the

coil’s motion in different positions, and if the running of movable parts cannot

be violated, or if a crossing cannot occur whereby the e.g. coil’s core or

switching-off mechanism motion could be disabled. This result can exercise a

significant influence on the fact if the DPN in an inconvenient position does

not switch-off sufficiently fast in case of a short-circuit, or if it does not

react at all, or if it changes its characteristic curve.

It is excluded in case of our DPNs because we have managed it in following

way:

1) by design:

The design of the electromagnetic high-speed release with ejecting cage for

short-circuit protection has been solved so that it has not any adjustable

element. Its characteristic is given by cross-section of the copper wire of the

coil, by number of threads and spring pre-stressing in the core. This solution

thus excludes that our DPNs could change their presented characteristic curve by

a fall, shock or bedding in another installation position.

The DPNs BONEGA®are protected against avoiding the short-circuit release to

be put out of service by a suitable seating of the structure elements,

especially of the ejecting coil which is seated in a unique “cradle” (see

“guaranteed reliability”). This design has excluded the possibility to misalign

and consequently to seize the movable core at the coil.

2) by seating itself

The ejecting coil is seated in the case so that the core’s motion direction,

when ejecting, goes against the gravitational force (also upwards). From the

resistance’s point of view, it is the most unsuitable position. In this

position, the DPN´s parameters are set up. Therefore, any other installation

position is only for the benefit of switch-off rate. The gravitational force

helps for safety in any other positions.

14. Quick Removal of the DPN from the DIN Strip

You need not dismantle the

interconnecting strip.

|

A unique auxiliary mechanism allows an easy removal

of a DPN. |

Play animation

|

Other advantages of this solution:

- the mechanism does not fall out from the DPN body

- it has a locking in extreme positions

- it has no steel spring, so it does not subject to climate influences

15. Higher Safety Standards

The casing design protects against an

injury by current when being touched by a finger.

By a suitable casing design, all the terminals are protected against a finger

touch or penetration of strange small objects (it complies with the

protection IP 20).

top

top

16. Superior Cover Design

The screws on the clip terminals are kept

from falling out

of the DPN body by our unique design.

The clip terminals are seated in the DPN casing so that the

screws of the terminals cannot fall out from the DPN body, even if

they are fully unscrewed from the terminal. This advantage has been reached

because the diameter of the hole at the plastic box (casing) for a screwdriver

is less than the diameter of the screw head. The screw head has been modified

both for cross and flat screwdrivers.

17.

ATTACHMENT EVEN ONTO DIN STRIPS WITH DIFFERENT THICKNESS

You will not be surprised by nonstandard

DIN strips

The DPNs are primarily intended to be attached on the strip DIN EN 50 022

(width - 35 mm, with the thickness range 0,8 - 2 mm). In the European market,

there are also the DIN strips outside the above range. The design of the movable

and fixed pawls of the DPN BONEGA® P-E-P allows attaching the devices even onto

less exact DIN strips.

top

top

18. A Pawl with Unique Characteristics

Quick installation and release.

The fastening mechanism with a movable pawl enables, as follows:

a) the DPN can be fastened to the DIN strip by a simple

“snapping”

-

Move the pawl from the B position into the A position (the

production position), if is has not been done yet.

-

Suspend the DPN in the upper on a projection on the DIN

strip’s upper part and snap it on the DIN strip’s bottom part with a

swinging motion.

b) the fast dismantling from the DIN strip

|

1

2

3

|

-

From the fixed condition in the position 3, move the pawl to

the Pos. 1 by means of e.g. screwdriver, which is to be put through the pawl

hole and to be drawn-half out.

-

The pawl keeps arrested in the Pos. 1 and the screwdriver

can be removed.

-

Now remove from the DIN strip.

The installation is essentially easier and faster with the DPN´s

BONEGA® P-E-P.

top

top

19. Extraordinary DPN's Body Strength

Extended mechanical reliability

|

The rigidity s given:

- By a highly sophisticated selection of a point for rivets

- By a number of rivets

- By the design of the case

|

20. ColoUred Control Levers

The colored levers increase the clear

arrangement and comply with the requirements of power-supplying plants.

We supply both the color version pursuant to the values of nominal currents

(which correspond to the indication of cap fuses) as a standard, and the black

version upon requirement.

|

6 A |

Green |

|

|

10 A |

Red |

|

|

13 A |

Sand |

|

|

|

16 A |

Grey |

|

|

20 A |

Blue |

|

|

25 A |

Yellow |

|

|

32 A |

Violet |

|

|

top

top

21. Sealing Under Certain Conditions

The ability to seal the lever in an ON

or OFF position.

|

The lever can be sealed because of openings in both guiding sidewalls of the

switch-off lever. Through these openings, a sealing wire can be fed. This

sealing wire passes also through a groove on the movable lever. This groove has

been engraved in OFF and ON positions and it disables the motion of the

lever itself.

If the lever is sealed in the ON position, the immobility does not render

the function of the DPN impossible. In the event of

short-circuit or overload, the circuit will be shutdown (independently on the

fixed position of the lever). The DPN case enables the lever to be sealed

independently on placing the adjacent DPN´s.

|

|

22. Smoother than any Switch you'll Find

You'll think it's not even on ...

The most excellent and balanced design of a switching mechanism. Extremely

easy running when switching-on the lever even in case of multi-pole models.

top

top

Export Manager: Michal Hudeček, tel: +420 605 518 724,

[email protected]

Sales Department: - Mrs Adriana Jamná,

fax +420 518 335 216, email : [email protected],

696 66 Sudoměřice nad Moravou 302

The

extraordinary small dimensions (especially the height is only 81 mm) rank the

DPN BONEGA® P-E-P to the smallest ones worldwide within the category of the

breaking capacity up to 6 kA.

The

extraordinary small dimensions (especially the height is only 81 mm) rank the

DPN BONEGA® P-E-P to the smallest ones worldwide within the category of the

breaking capacity up to 6 kA.