Superior security and protection

1. Extraordinary High-Speed Break

The sooner the entire

short-circuit process is terminated, the less damage there is

to connected devices

and wiring.

The BONEGA® P-E-P MCB's have reached the highest breaking

rate of any MCB (from 2 to 5 times higher than any other MCB).

An extraordinary high breaking rate beginning from the initiation of a

short-circuit to its termination amounts to max. 5 ms (with a maximum

load).

The BONEGA® P-E-P MCB's do not reach that high rate to the detriment of the

higher arc voltage which raises the risk of protected parts (e.g. motors)

considerably. As compared to other MCB´s, the arc voltage is equal or lower.

The high-speed switch-off consists of three stages:

- stage 1 – disconnection of contacts

- stage 2 – arc running into the chamber

- stage 3 – arc burning termination

The principal advantage of our MCB´s consists of an extraordinary high speed

within the first two stages. The third stage is very quick, as well, but it is

not so essential in the framework of the total speed. Within this last stage, it

is most essential that the chamber is so well constructed that the arc does not

“jump-out” in any direction (especially it does not come back to the contacts at

all).

An almost textbook run of the short-circuit process is caused also by the

suitable adjustment of the contact thrust. These contacts do not deviate by

the influence of aerodynamic forces (as obvious from the

charts).

Note: Some producers mention only the speed of contact disconnection (which is

the first stage) instead of the total breaking speed. In the moment of contact

disconnection, the power is still flowing through the circuit (voltage and

current) because of the created arc. In this stage, the MCB has not disconnected

the circuit yet.

Conclusion:

- Our curve of breaking procedure is fully unique (an example how an MCB should protect).

- The extremely

high breaking rate will not endanger the end user, but – in contrast – it

will protect him better

- The extraordinary breaking rate of the BONEGA® P-E-P MCB's provides the

most sensitive protection

of human lives, electrical devices within a circuit, and wiring itself.

More information: oscilograms and graphs

to the top

to the top

2. Guaranteed Short-Circuit Resistance

The MCB's BONEGA® P-E-P

can be used under

the most difficult short-circuit conditions.

Our primacy consists in the breaking capacity of 10 kA up to the highest

value of 63A, even with the curve “D” pursuant to CSN EN 60898 (nobody has

reached it yet).

Our worldwide uniqueness consists in integration of the following

phenomena with the kept breaking capacity of 10 kA:

I.) It is necessary to be aware of that

the inside MCB´s resistance affects – inter alia – the breaking capacity.

With the low nominal values (e.g. 1A), almost every producer can pride

himself that his MCB theoretically has an unlimited breaking capacity.

The higher is the nominal current, the lower is the assistance of the inside

MCB´s resistance to absorb the short-circuit process. The nominal current

crucial value is at 25A MCB´s and the very critical ones is at the highest

value, i.e. 63A within the curve “D”. If the experts want to detect the MCB´s

quality, so they always use the aforementioned crucial values (25A and 63A).

Within these values, the design of the breaking mechanism, contacts,

extinguishing chamber etc. becomes known very clearly.

The essential difference, as compared to the MCB´s of

several producers, consists in the reached range of nominal currents,

which is reached with the mentioned breaking capacity (25 kA, 15kA, 10kA, 6kA

...). We are preparing the upper limit of the nominal currents, which can be

reached by our MCB´c within their breaking capacity 25 kA and 15kA.

II.) Another important difference consists in the standard, in

accordance with which the producer has achived his certification. In Europe,

there are two basic standards, namely:

a) the so-called „industrial“ standard CSN EN 60947

b) the so-called „household“ standard CSN EN 60898

As to their relations to breaking capacities, the standards differ e.g. in their

requirements of short-circuit quantity, which a MCB has to withstand without

disablement of its function. That means one short circuit pursuant to the

standard ČSN EN 60947 and three successive short-circuits pursuant to the

standard ČSN EN 60898.

As resulting from the above, the industrial standard is significantly softer.

For many people, that requirement of the standard seems to be illogical, but is

takes into consideration the behavior of a user, after the circuit has been

broken by a MCB. The reaction of the user in a household often is that he tries

to switch-on the MCB for the first, second and third time and just after that he

begins to trace the cause. In contrary, a professional electrician tries to

switch-on it only once and if the MCB breaks again, he begins to trace the cause

immediately.

III.) Take into account also the third significant difference – the

width of a MCB. There are some MCB´s with an even higher breaking capacity,

but they are in a 1,5-modular or double-modular design.

Notice at other producers, according to which standard and up to which

nominal current values they mention the breaking capacity. You can be

surprised by the results of worldwide-accredited producers.

The above parameters are caused by the distinguishing chamber, which is

one of our two worldwide-acknowledged Czech patents within the MCB P-E-P. Its

extraordinary properties could be seen also at the prepared DPN (there is a MCB

+ switch within one module of 17,5 mm). In this case, we have also overcame the

breaking capacity limitation of 4,5 kA which had been reached worldwide pursuant

to the standard ČSN EN 60898.

The MCBˇs with a short-circuit resistance up to 15 kA are tested now. As to

the single-modular design of those MCB´s (width 17,5 mm) and the given range

of nominal currents, we would be the only ones worldwide. The prepared MCB´s

BONEGA® P-E-P with the breaking capacity of 15 kA can find their application

especially in special works where they can replace the 1,5 or double modular

MCB´s.

3. Reduction of Undesirable Power During a Short-Circuit

The lower the power within a short-circuit,

the less damage to the connected devices

and wiring.

It is a very important property of a MCB, which is often marginalized by the

public.

The quality of the MCB protection is also conditioned by the amount of power

that “flows” through the MCB during short-circuit. Its amount is given by the

relation: E = I2.t.

As resulting from the mentioned relation, the high breaking rate of the MCB´s

BONEGA® P-E-P reduces that undesirable power.

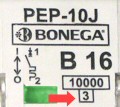

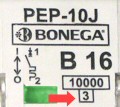

The standard CSN 60898+A1/A11 states the power limits based of which the MCB´s

are classified. The category (class) is mentioned on a MCB in the frame below

the breaking capacity.

Our MCB´s reach the limits of the 3rd (the highest possible) class without power

limitation pursuant to CSN 60898+A1/A11, namely even with the nominal breaking

capacity of 10 kA.

The following tables show the requirements of the standard for the MCB up to 16A

and above 16A up to 32A incl., at various nominal short-circuit capacities.

The power limiting class reached by a MCB is an essential element for

assessment of its protective function. We have met the third power limiting

class within the whole range requested (as one of few producers), even with the

rated short-circuit capacity of 10 kA. The following tables present e.g. the

standard requirements for the MCB up to 16 A, and above 16A up to 32A incl. with

different rated short-circuit capacities.

| Permitted values I2t for the MCB´s with the rated

current up to 16 A incl. |

| Rated short-circuit capacity

(A) |

Power limiting classes

|

|

1

|

2

|

3

|

|

max. I2t

A2s

|

max. I2t

A2s

|

max. I2t

A2s

|

|

type B a type C

|

type B

|

type C |

type B

|

type C |

| 3 000 |

The limits not stated

|

31 000 |

37 000 |

15 000 |

18 000 |

| 4 500 |

60 000 |

75 000 |

25 000 |

30 000 |

| 6 000 |

100 000 |

120 000 |

35 000 |

42 000 |

| 10 000 |

240 000 |

290 000 |

70 000 |

84 000 |

|

(the values written in bold digits are valid for our

MCB´s BONEGA®, series P-E-P):

|

| Permitted values I2t for the MCB´s with the rated

current above 16 A and up to 32 A incl. |

| Rated short-circuit capacity

(A) |

Power limiting classes

|

|

1

|

2

|

3

|

|

max. I2t

A2s

|

max. I2t

A2s

|

max. I2t

A2s

|

|

type B a type C

|

type B

|

type C |

type B

|

type C |

| 3 000 |

The limits not stated

|

40 000 |

50 000 |

18 000 |

22 000 |

| 4 500 |

80 000 |

100 000 |

32 000 |

39 000 |

| 6 000 |

130 000 |

160 000 |

45 000 |

55 000 |

| 10 000 |

310 000 |

370 000 |

90 000 |

110 000 |

|

(the values written in bold digits are valid for our

MCB´s BONEGA®, series P-E-P):

|

to the top

to the top

4. Locking Protection

The BONEGA® P-E-P

MCB´s cannot be locked from the outside.

|

red I - ON

green O - OFF

|

As the most products, also the MCB´s BONEGA® P-E-P has an

indication of the contact conditions. That indicates a real contact condition

and not only a position of the switch-on lever. In case of “sintered” contacts

and switched-off lever, the user is clearly informed about flowing current. As

the only ones, our MCB´s have that indication

|

Reasons:

- Because the indication is closely connected with a movable contact, it

happens on other MCB´s that the movable contact is locked through the

indication by means of a toothpick or a matchstick; thus the complete

thermal and short-circuit protection of a MCB is out of function. It is

not possible to do this on the MCB BONEGA® P-E-P, just because of that

transparent sight-glass

- Dust protection

This property protects the electro installation companies against

claims, which are caused by the end user, who can be proved wrong with

difficulties.

The philosophy of the colored indication ON/OFF is explained within

frequent questions.

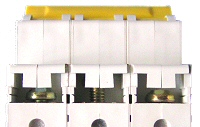

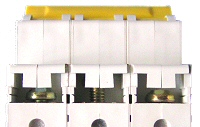

5. Simultaneous Switching of the Multi-Module's

Connected devices are

less strained.

A worldwide unique recently patented system of triggering mechanism which

ensures a safe, more accurate and simultaneous switching of all the

contacts at multi-module (pole) miniature circuit breakers; it has been reached a three-times

longer switching distance than that reached by the best competitors world-wide.

This advantage enable e.g. continuous start of multi-fuse electric motors

(all fuses are switched at the same time).

to the top

to the top

6. Revolutionary Designed Extinguishing Chamber

The extinguishing

chamber affects the breaking speed

and breaking capacity.

The extinguishing chamber is of a fully new patent-protected conception.

a) a very fast “drawing-in” of an arisen electric arc into the chamber

When the movable contact is disconnected from the fixed one, it is necessary

to “draw-in” the arisen arc into the extinguishing chamber as soon as possible

and to interrupt the circuit definitely. The MCB´s BONEGA® P-E-P do not reach

that high rate to the detriment of the higher arc voltage which rises the risk

of protected parts (e.g. motors) considerably. This could be reached e.g. by

higher number of sheets at the extinguishing chamber. Our chamber has only usual

13 interruptions. As compared to other MCB´s, the arc voltage within the MCB´s

BONEGA® P-E-P is equal or rather lower.

b) it is not possible the arc to return to the contacts

In other MCB´s, the arc can return to the contacts, so the circuit is connected

again. Thanks to the design of the chamber, this phenomenon is not possible in

the MCB´s BONEGA® P-E-P.

c) fast arc extinction

The sooner the arc is extinguished, the smaller amount of heat arises. This

heat can affect the adjacent circuits (warming of an adjacent MCB)

d) utilization of cold air at the extinguishing chamber for cooling the

contacts

At the beginning of short-circuit process, the non-warmed air inside the

chamber is used for cooling the contacts immediately before they are

disconnected

7. Durability

Impact resistant.

|

The design of the electromagnetic high-speed release with ejecting armature

for short-circuit protection has been solved so that it has not any adjustable

element. The characteristic is given by the cross-section of the copper wire of

the coil, by number of threads and spring pre-stressing in the core. This

solution thus excludes that our circuit breakers could change their presented

value by a fall or shock.

to the top to the top

|

8.

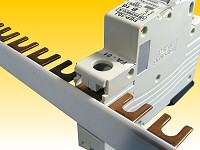

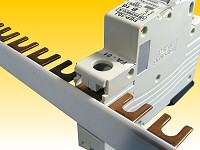

Terminal Resistant to Inter-Phase Short-Circuit

MCB BONEGA® P-E-P

eliminates danger of inter-phase short-circuit e.g. just by air ionization.

At the upper part of the terminal (serving for interconnection by means of

forked strip), the MCB´s body is equipped with partitions which can be broken of.

Those partitions shall avoid a possible inter-phase short-circuit in case of

interconnection of multi-module types by means of multi-phase interconnecting

strips. This short-circuit can be caused by air ionization or humidity, that

support electric arc.

9. Vibration Resistance

The BONEGA® P-E-P

MCB´s can be used in equipment with strong vibrations (e.g. railway wagons, site

switchboards).

Strong vibrations can cause the short-circuit release to be put out of service

(it loses its protective function) or the spot-welds to be disconnected (current

interruption).

a) measures avoiding the short-circuit release to be put out of service

|

The MCB´s BONEGA® P-E-P are protected against the above phenomenon by a

suitable seating of the structure elements, especially of the ejecting coil

which is seated in a unique “cradle” (see the Fig.). This design has excluded

the possibility to misalign and consequently to seize the movable core at the

coil. |

b) measure avoiding the spot welds to be disconnected

The quantity of spot-welds can be reduced significantly. The elements are

interconnected by means of a modular design, or he parts are made of one piece.

to the top

to the top

10. Protection Against Hacking of an MCB

We comply with the

requirements of distribution

companies for disassembly protection.

The multi-pole MCB´s BONEGA® P-E-P cannot be disassembled in such a way that

only the interconnection between stretching levers would be removed and the

individual poles could function separately (e.g. through this, the day and night

tariff rate could be influenced). Especially the distribution companies call for

this property.

The mutual phases interconnection does not happen just between the levers, but

also by means of pins which are put between the pole and they interfere directly

into the inside mechanisms through a side hole. In addition, the multi-pole

design is connected with rivets. The interconnecting and covering strip, which

is between the levers, is visibly depreciated. Any interference in a MCB

is obvious at first sight.

11. Higher Safety Standards

Construction of the cover

eliminates electrical current injury

caused by touching the circuit breaker.

All locking bars are protected against danger touch and penetration of

small foreign objects (IP protection 20).

to the top

to the top

12. Wide Selectivity

The MCB´s can be used

within combined projects.

The selectivity means a coordination of two successive

breaking devices so that just the disabled wiring part can be switch-off upon a

failure. A wide scale of current values and curves B, C and D

enables our MCB´s to be put together to various safety cascades. Because of the

above, the desired selectivity can be reached.

13. Colored Control Levers

The colored levers

improve the transparency and comply with the requirements of power plants.

We supply both coloured levers in accordance with the nominal current

values (corresponding to the marking of turn fuses) and black levers.

|

0,2 A - 1,6 A |

black |

|

|

2 A |

pink |

|

|

4 A |

brown |

|

|

6 A |

green |

|

|

8 A |

light green |

|

|

10 A |

red |

|

|

13 A |

sandy |

|

|

|

16 A |

grey |

|

|

20 A |

blue |

|

|

25 A |

yellow |

|

|

32 A |

purple |

|

|

40 A |

black |

|

|

50 A |

white |

|

|

63 A |

copper-coloured |

|

|

14. Sealing Under Certain Conditions

The ability to seal the

lever in an ON or OFF position.

|

The lever can be sealed because of openings in both guiding sidewalls of the

switch-off lever. Through these openings, a sealing wire can be fed. This

sealing wire passes also through a groove on the movable lever. This groove has

been engraved in OFF and ON positions and it disables the motion of the

lever itself.

If the lever is sealed in the ON position, the immobility does not render

the function of the circuit breaker impossible. In the event of

short-circuit or overload, the circuit will be shutdown (independently on the

fixed position of the lever). The MCB case enables the lever to be sealed

independently on placing the adjacent MCB´s.

|

to the top to the top

|

Export Manager: Michal Hudeček, tel: +420 605 518 724,

[email protected]

Sales Department: - Mrs Adriana Jamná,

fax +420 518 335 216, email : [email protected],

696 66 Sudoměřice nad Moravou 302